Introduction to Sustainable Silk Production

The world of luxury textiles is undergoing a transformation as consumers increasingly seek products that align with their environmental and ethical values. At the heart of this shift is sustainable sericulture—the practice of silk production with minimal negative impact on our planet and its inhabitants.

Low-impact silk production encompasses a holistic approach to creating this luxurious fabric while carefully considering:

- Environmental footprint reduction through resource conservation

- Ethical treatment of silkworms and fair labor practices

- Reduced chemical usage in cultivation and processing

- Preservation of biodiversity and ecosystem health

The conventional silk industry, despite producing a beautiful natural fiber, faces significant sustainability challenges. Traditional methods often involve high water consumption, chemical-intensive processes, and ethical concerns regarding silkworm treatment. As the textile market evolves, the demand for sustainable alternatives has grown by over 60% in recent years, demonstrating a clear shift in consumer priorities.

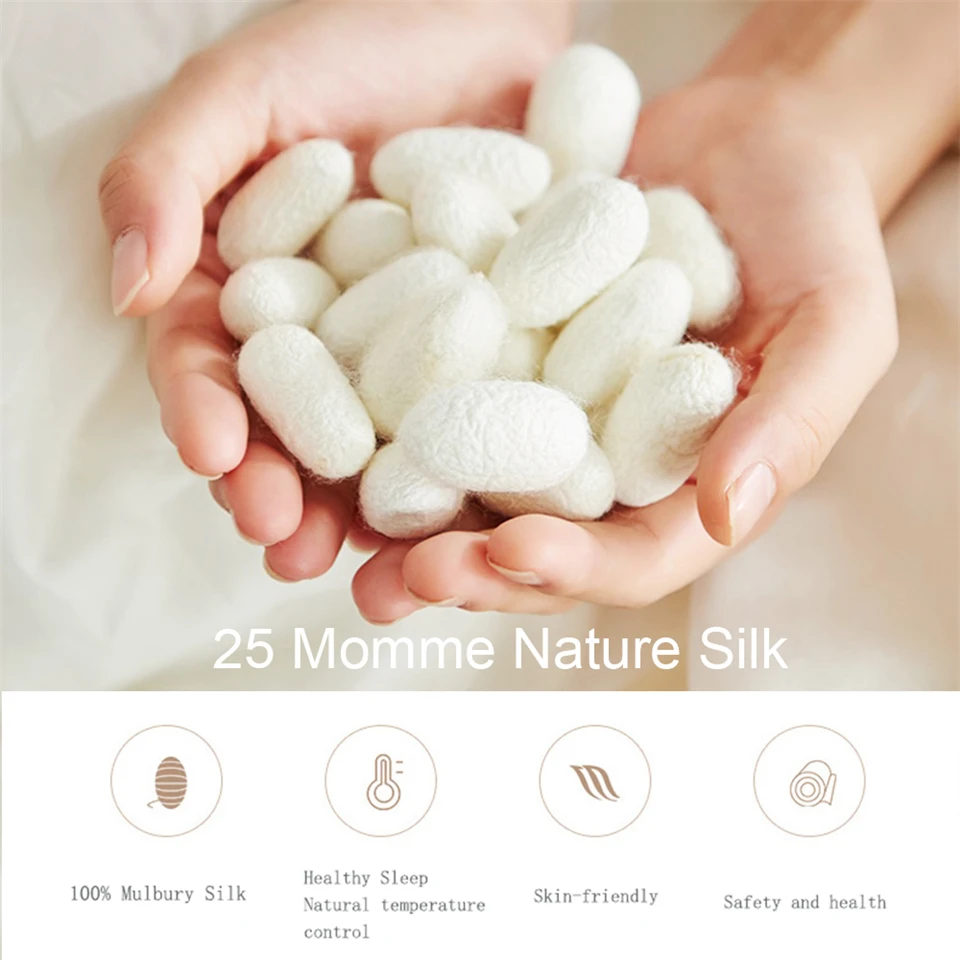

Understanding the amazing benefits of mulberry silk sheets helps us appreciate why finding sustainable production methods matters so much. The quest for more eco-friendly silk production represents not just a trend but a necessary evolution in how we create luxury textiles for the future.

Understanding Conventional Silk’s Environmental and Ethical Impact

Environmental Footprint

Traditional silk production comes with substantial environmental costs that often go unseen behind the lustrous final product. Conventional sericulture requires approximately 1,500 gallons of water to produce just one pound of raw silk—significantly higher than many other natural fibers. This intensive water usage places strain on local water supplies, particularly in regions already facing scarcity.

The cultivation of mulberry trees, the silkworm’s sole food source, traditionally relies on synthetic pesticides and fertilizers that contaminate soil and waterways. During processing, harsh chemicals used in degumming (removing sericin, the sticky protein coating silk fibers) and dyeing create toxic wastewater that often enters ecosystems without adequate treatment.

Energy consumption throughout conventional production further contributes to silk’s carbon footprint, with some estimates suggesting that silk has a higher per-weight carbon impact than many synthetic fibers.

Ethical Considerations

The traditional method of harvesting silk involves boiling silkworm cocoons while the pupae are still alive inside, killing approximately 3,000 silkworms to produce a single pound of silk. This practice raises significant animal welfare concerns among ethically-minded consumers.

Labor practices in major silk-producing regions also present challenges, with workers sometimes facing poor conditions, inadequate compensation, and exposure to harmful chemicals without proper protection.

Understanding the complete guide to mulberry silk bed sheets provides context for why these traditional methods have persisted but also why alternatives are increasingly important.

Core Principles of Low-Impact Silk Production

Sustainable silk production is guided by several fundamental principles that work together to minimize negative impacts while maintaining the quality and beauty of this precious fabric.

The cornerstone principles of low-impact sericulture include:

- Compassionate animal treatment: Implementing non-violent approaches to silk harvesting that allow silkworms to complete their natural lifecycle

- Resource efficiency: Minimizing water usage, energy consumption, and material waste throughout the production process

- Chemical reduction: Eliminating or significantly reducing synthetic pesticides, fertilizers, and processing chemicals

- Ecosystem enhancement: Implementing cultivation practices that promote biodiversity, soil health, and ecological resilience

- Fair labor practices: Ensuring safe working conditions, fair wages, and empowerment for workers across the supply chain

- Transparency: Maintaining open communication about production methods and supply chain practices

These principles represent a holistic approach that considers every aspect of silk’s journey from mulberry leaf to finished fabric. By understanding what makes mulberry silk special, producers can preserve its unique qualities while implementing sustainable practices.

The market for mulberry silk bedding sets produced using these principles continues to grow as consumers recognize the importance of aligning luxury purchases with environmental and ethical values.

Peace Silk (Ahimsa Silk): Non-Violent Sericulture

Peace silk, also known as Ahimsa silk (from the Sanskrit word meaning “non-violence”), represents one of the most significant ethical advancements in sericulture. This compassionate approach allows silkworms to complete their natural lifecycle rather than interrupting it through traditional harvesting methods.

The peace silk production process follows these key steps:

- Silkworms feed on mulberry leaves and form their cocoons normally

- Instead of harvesting cocoons with the pupae inside, producers wait 7-10 days

- Moths naturally emerge from their cocoons, breaking through the continuous silk filament

- After the moths complete their lifecycle (mating and egg-laying), the empty cocoons are collected

- The broken silk filaments are carefully gathered and spun into yarn using special techniques

This method produces silk with distinct characteristics—the fibers are shorter (since the continuous filament is broken) and have a more textured feel with a subtle, natural luster that differs from conventional silk’s high shine.

While peace silk addresses the primary ethical concern in sericulture, it does present certain challenges. The process is more labor-intensive and time-consuming, resulting in higher production costs—typically 1.5-2 times that of conventional silk. Additionally, the moths that emerge from these cocoons are domesticated Bombyx mori silkworms that have been selectively bred for thousands of years and cannot fly or feed as adults, raising nuanced ethical questions about their brief post-emergence existence.

Peace silk represents an important option for those seeking silk sheets produced with animal welfare as a priority, though it involves considering these complex ethical and practical tradeoffs.

Organic Silk: Chemical-Free Cultivation

Organic silk production focuses primarily on environmentally responsible mulberry cultivation and processing methods. By eliminating synthetic chemicals throughout the production process, organic silk significantly reduces environmental impact while creating a purer final product.

Key practices in organic silk cultivation include:

- Natural pest management: Using beneficial insects, companion planting, and physical barriers rather than synthetic pesticides

- Organic fertilization: Implementing compost, manure, and other natural amendments to build soil health without synthetic fertilizers

- Crop rotation and diversity: Planting complementary crops alongside mulberry to enhance soil fertility and prevent pest buildup

- Buffer zones: Maintaining undisturbed areas around mulberry plantations to support beneficial insects and biodiversity

The environmental and health benefits of organic silk are substantial. Studies show that organic mulberry plantations support 30-50% more biodiversity than conventional ones. By eliminating pesticide runoff, these methods help preserve water quality in surrounding ecosystems and reduce chemical exposure for workers and local communities.

For consumers seeking the highest standards, look for Global Organic Textile Standard (GOTS) certification. This internationally recognized standard verifies that the entire production process—from cultivation through processing—meets strict environmental and social criteria.

While organic silk addresses many environmental concerns, it’s worth noting that it may still use traditional harvesting methods. For those seeking both chemical-free and cruelty-free options, vegan silk bedding offers an alternative approach to luxurious bedding without animal products.

Regenerative Silk Farming: Beyond Sustainability

Regenerative silk farming represents the frontier of sustainable sericulture by going beyond simply reducing harm to actively restoring and enhancing ecosystems. This approach treats silk production as an opportunity to heal damaged landscapes and create positive environmental impacts.

Regenerative silk farming implements advanced ecological practices:

- Carbon sequestration: Using specific cultivation methods that maximize carbon capture in soil, helping mitigate climate change

- Water cycle restoration: Implementing water harvesting techniques, contour planting, and soil building to improve water retention and reduce runoff

- Biodiversity integration: Creating intentional ecosystems where mulberry trees coexist with diverse plant and animal species

- Agroforestry systems: Combining mulberry trees with other productive and native plant species in layered systems that mimic natural forests

The benefits extend far beyond the silk itself. Farms transitioning to regenerative methods have documented 40-60% increases in soil organic matter over 5-10 years, dramatically improving soil fertility while reducing irrigation needs. Biodiversity studies show 3-5 times more beneficial insect species in regenerative systems compared to conventional monocultures.

One pioneering silk farm in India documented a 300% increase in water retention capacity after implementing regenerative practices for five years, allowing for continued production during drought periods while neighboring conventional farms struggled.

These approaches create silk production systems that become increasingly productive and resilient over time—the opposite of conventional agriculture’s tendency toward soil degradation and increasing chemical dependency.

Eco-Friendly Processing and Dyeing Methods

The processing stage of silk production often creates significant environmental impacts through water consumption, chemical use, and energy demands. Eco-friendly processing methods address these concerns while maintaining silk’s exceptional qualities.

Water-Efficient Processing

Innovative producers have developed methods that dramatically reduce water usage:

- Low-water immersion dyeing can reduce water consumption by 70-80% compared to traditional methods

- Closed-loop water recycling systems filter and reuse water multiple times before treatment

- Advanced waterless processing technologies use CO2 or air-based methods for certain steps

One silk mill in India implemented a comprehensive water recycling system that reduced freshwater requirements by 85% while maintaining production volumes.

Natural and Low-Impact Dyes

The shift away from synthetic dyes addresses both environmental and health concerns:

- Plant-based dyes derived from sources like indigo, madder root, and walnut hulls offer beautiful, complex colors

- Non-toxic synthetic alternatives developed specifically for reduced environmental impact

- Improved fixation methods that reduce color bleeding and extend product lifespan

Natural dyes typically require additional mordants (fixing agents) to achieve color fastness comparable to synthetic dyes. Eco-friendly producers use alum and other low-impact mordants rather than heavy metals.

Degumming Alternatives

Traditional degumming uses harsh alkaline soap solutions that create significant wastewater issues. Sustainable alternatives include:

- Enzyme-based degumming that works at lower temperatures with biodegradable results

- Citrus-based solvents that effectively remove sericin with reduced environmental impact

- Modified soap solutions with improved biodegradability and reduced chemical load

By implementing renewable energy sources throughout processing facilities, forward-thinking producers further reduce environmental impact. The vegan silk sustainable production process incorporates many similar eco-friendly processing techniques to achieve comparable luxury with different raw materials.

Waste Reduction and Circular Economy in Silk Production

Creating truly sustainable silk requires addressing the entire lifecycle of products, with particular attention to minimizing waste and finding productive uses for byproducts. Innovative approaches are transforming what was once considered waste into valuable resources.

Comprehensive waste reduction strategies include:

- Pattern optimization that reduces fabric waste during cutting by 15-30%

- Collection and repurposing of mulberry pruning waste as natural dyes or biomass fuel

- Recapturing sericin (the protein removed during degumming) for use in cosmetics and pharmaceuticals

- Converting silkworm waste into organic fertilizer for mulberry trees, creating a closed-loop system

Recycling and upcycling innovations are giving silk new life beyond its initial use:

- Technologies that break down silk fabric waste into fiber that can be respun

- Creative upcycling of silk scraps into patchwork products, accessories, and home goods

- Development of silk composite materials that incorporate reclaimed silk for industrial applications

Some producers achieve near-zero waste through holistic approaches that find uses for every byproduct of the silk production process. For example, silkworm pupae (after humane natural death in peace silk production) provide protein-rich food in some cultures and valuable oil for cosmetic applications.

For consumers seeking pure luxury with sustainable production methods, 100% silk sheets made with waste-conscious approaches offer both indulgence and environmental responsibility.

Comparing Low-Impact Silk Methods: Benefits and Tradeoffs

Each sustainable silk production approach offers distinct advantages and considerations. This comprehensive comparison helps consumers and producers understand which methods align best with specific priorities.

| Production Method | Animal Welfare | Environmental Impact | Fiber Quality | Cost Factor | Market Availability |

|---|---|---|---|---|---|

| Conventional Silk | Low (silkworms killed) | High water/chemical usage | Long fibers, high luster | Baseline price | Widely available |

| Peace Silk (Ahimsa) | High (moths emerge naturally) | Moderate water/chemical usage | Shorter fibers, textured feel | 1.5-2x conventional | Limited but growing |

| Organic Silk | Varies (may still kill silkworms) | Low chemical, moderate water usage | Similar to conventional, pure | 1.3-1.8x conventional | Moderate availability |

| Regenerative Silk | Varies (depends on harvesting) | Positive environmental impact | Similar to organic with terroir variation | 1.5-2.5x conventional | Very limited, specialized |

Quality considerations vary significantly between methods. Peace silk typically offers a more textured, rustic appearance with slightly reduced tensile strength compared to conventional silk. Organic silk maintains qualities very similar to conventional silk but without chemical residues. Regenerative silk often develops unique “terroir” characteristics reflecting its specific growing environment.

Cost differences reflect the additional labor, time, and specialized knowledge required for sustainable methods. While conventional silk might cost $50-70 per yard for fabric, peace silk might range $75-140, and regenerative silk could reach $120-180 for comparable weights.

Consumer priorities ultimately determine which method represents the best value. Those prioritizing animal welfare might prefer peace silk despite its higher cost and textural differences. Those focused primarily on environmental impact might choose regenerative methods, while those seeking a balance of sustainability factors might select organic silk.

Understanding how vegan silk is made provides additional context for those considering alternatives beyond traditional silk.

Certifications and Standards in Sustainable Silk

Navigating the complex world of sustainable silk becomes easier with trusted third-party certifications. These standards provide verification that products meet specific environmental and ethical criteria.

Global Organic Textile Standard (GOTS)

GOTS certification represents the gold standard for organic textiles. For silk to earn this certification, it must:

– Be grown without synthetic pesticides, herbicides, or fertilizers

– Undergo processing without harmful chemicals listed on their prohibited substances list

– Be manufactured in facilities that meet strict wastewater treatment standards

– Be produced under fair labor conditions with proper worker protections

OEKO-TEX Standard 100

This certification focuses specifically on the final product’s safety for human use, testing for:

– Regulated and unregulated harmful substances

– Pesticide residues and allergy-inducing dyes

– Heavy metals and other potential contaminants

– pH levels and color fastness

While OEKO-TEX doesn’t specifically address production methods, it ensures the end product is safe for consumers.

Other Relevant Certifications

Several other standards provide additional verification:

– Soil Association Organic Standard (UK-based organic certification)

– PETA-Approved Vegan (for silk alternatives)

– Fair Trade Certified (focusing on worker conditions and fair compensation)

– Bluesign® (addressing environmental health and safety throughout production)

Traceability systems are increasingly important for verifying sustainable claims. Advanced producers implement blockchain or QR code systems allowing consumers to track their specific product from mulberry leaf to finished fabric.

When shopping for sustainable silk products, look for these certification logos on packaging and product descriptions, and don’t hesitate to ask brands about their specific certification status.

Ethical Alternatives to Silk: Plant-Based and Innovative Fibers

For those seeking the luxurious feel and properties of silk without any animal products, several innovative alternatives offer compelling options:

Plant-Based Silk Alternatives

Lyocell (Tencel™): Made from sustainably harvested wood pulp using a closed-loop production process that recycles 99% of chemicals and water. Offers exceptional drape, breathability, and temperature regulation similar to silk.

Cupro: Created from cotton linter (the fine, silky fibers that stick to cotton seeds), this fabric provides an elegant drape and smooth texture comparable to silk. Production requires careful chemical management but utilizes what would otherwise be agricultural waste.

Bamboo Silk: Derived from fast-growing bamboo, this alternative offers silky smoothness and natural temperature regulation. Production methods vary significantly in environmental impact, with mechanical processing being more sustainable than chemical.

Fruit Fiber Silks: Innovative textiles made from agricultural waste like orange peels, banana stems, and pineapple leaves. These materials repurpose what would become waste while creating fabrics with silk-like qualities and unique character.

Hemp Silk: Advanced processing techniques can transform hemp into incredibly soft, flowing fabric with excellent moisture-wicking properties and natural antibacterial qualities similar to silk.

Biotechnology Innovations

Research labs are developing lab-grown silk proteins that mimic natural silk without silkworms. These bioengineered proteins can be customized for specific properties like enhanced strength or stretch while eliminating animal welfare concerns.

When comparing alternatives to traditional silk, consider:

– Breathability: Most plant-based alternatives offer good breathability, with Tencel and hemp performing particularly well

– Drape: Cupro and Tencel provide the closest match to silk’s elegant drape

– Durability: Hemp silk and some bio-engineered options may exceed natural silk’s durability

– Care requirements: Many alternatives are easier to care for than traditional silk, often being machine-washable

Bamboo silk sheets represent one of the most widely available and affordable silk alternatives, offering many comparable benefits at a lower price point.

Is Low-Impact Silk Right For Your Bedding?

How does sustainable silk feel compared to conventional silk?

Low-impact silk maintains the luxurious, smooth feel that makes silk bedding so desirable. Peace silk has a slightly more textured finish with a subtle, natural sheen rather than high gloss. Organic silk feels virtually identical to conventional silk but without chemical residues that can affect the hand-feel over time. Many users report that sustainable silk actually feels better against their skin, particularly those with sensitivities.

Does sustainable silk require special care?

Most sustainable silk requires similar care to conventional silk—gentle washing with mild soap, cool water, and air drying. The absence of chemical finishes sometimes means sustainable silk needs slightly more careful handling initially, but this is offset by greater durability over time. Many eco-friendly silk producers provide detailed care guides specific to their production methods.

What are the skin and hair benefits of eco-friendly silk bedding?

Sustainable silk offers the same natural benefits that make conventional silk excellent for skin and hair—smooth surface that reduces friction, natural temperature regulation, and moisture-wicking properties. The additional advantage comes from what’s not there: chemical residues that might irritate sensitive skin. Many users with skin sensitivities report fewer issues with organic and peace silk products.

Is sustainable silk worth the higher price point?

When considering the 30-50% higher cost of sustainable silk, it’s important to evaluate the complete value proposition. Low-impact silk often demonstrates greater durability over time, maintaining its quality through more wash cycles. The environmental and ethical benefits represent real value that extends beyond the product itself. For many consumers, knowing their luxury bedding aligns with their values provides satisfaction that justifies the premium.

How long does low-impact silk bedding typically last?

Quality sustainable silk bedding, when properly cared for, can last 5-10 years or more—comparable to or exceeding conventional silk’s lifespan. The absence of chemical treatments often allows the natural fiber strength to persist longer, while the higher production standards associated with sustainable methods frequently result in superior craftsmanship.

Full-size Silk Sheets, King Size Silk Sheets, Queen Size Silk Sheets, Twin Size Silk Sheets, Washable Silk Sheets

Price range: $95.95 through $178.37 Select options This product has multiple variants. The options may be chosen on the product page100% Silk Sheets, Green Silk Sheets, King Size Silk Bedding Set, Mulberry Silk Bedding Sets, Queen Size Silk Bedding Set

Price range: $1,246.21 through $1,615.22 Select options This product has multiple variants. The options may be chosen on the product pageEucalyptus Silk Bedding Sets, Eucalyptus Silk Sheets

Price range: $360.24 through $393.60 Select options This product has multiple variants. The options may be chosen on the product pagePink Silk Sheets, Twin Size Silk Sheets

$171.80 Select options This product has multiple variants. The options may be chosen on the product pageFull-size Silk Sheets, Pink Silk Sheets

$136.31 Select options This product has multiple variants. The options may be chosen on the product pageGrey Silk Sheets, Silk Sheet and Pillowcase Set

Price range: $88.20 through $146.64 Select options This product has multiple variants. The options may be chosen on the product page

How Consumers Can Support Sustainable Silk Production

Your purchasing decisions have tremendous power to shape the future of silk production. By becoming an informed and intentional consumer, you can help drive the industry toward more sustainable practices.

To make the biggest positive impact:

Read labels carefully: Look beyond marketing terms like “eco-friendly” and seek specific information about production methods and certifications.

Ask detailed questions: When information isn’t readily available, contact brands directly with specific questions about their silk sourcing, animal welfare practices, and processing methods.

Extend product lifespan: Proper care significantly increases how long silk items last. Follow care instructions carefully, use gentle silk-specific detergents, and avoid direct sunlight when drying.

Support transparency leaders: Choose brands that openly share details about their supply chain and production methods, demonstrating commitment to continuous improvement.

Consider the full lifecycle: When purchasing silk products, think about their entire journey—from production through use and eventual disposal or recycling.

The most effective way to encourage sustainable practices is by demonstrating consumer demand through purchasing decisions. Every time you choose sustainable silk options like eucalyptus silk sheets, you send a clear signal to the industry about the importance of environmental and ethical considerations.

By combining consumer education with intentional purchasing, we can collectively transform silk production into a model of sustainability that preserves this extraordinary fabric’s luxury while respecting our planet and all its inhabitants.